Ad Learn Aspen Plus online at your own pace. The modeling of biomass gasification processes by simulators such as Aspen Plus is a powerful tool to assess mass and energy balances and to optimize process designs.

Aspen Plus Simulation Of Biomass Gasification In A Steam Blown Dual Fluidised Bed Semantic Scholar

Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierapwz a compound file containing these six files.

. Primary water gas reaction PWG C H 2 O CO H. The feed temperature is 800C and pressure is set to 1 bar. Normally undergraduate student projects will involve Aspen Plus or Aspen Properties.

The reaction kinetics of the model. The feed composition in Aspen Plus is specified as presented in Table 5. GUIExamplesEntrained Flow Coal Gasifier folder of the Aspen Plus installation.

The screenshots in this tutorial and some of the menus are outdated. In addition to the reactions in Table 1 combustion reactions will occur but these are omitted as Aspen Plus can generate them automatically and they depend on the composition of the fuel. A review of gasification models using ASPEN Plus process simulator is given by Puig-Arnavat et al.

Chapter 3 Aspen Plus Simulation 10 31 Assumptions 11 32 Gasification Reactions 11 33 Aspen Plus Model 12 331 Biomass Decomposition 12 332 Volatile Reactions 12 333 Char Gasification 12 34 Simulation Flow sheet 13 35 Characteristics of Raw Material 14 36 Simulation Analysis 15. Yes I have gone through it online. Δ H r 172 kJ kmol.

To start either of these packages be sure to look. Hi Muhammad I strongly recommend you to take a look at the work by a former member of my group. This textbook chapter provides tutorials for overcoming major challenges such as physical property package selection absorber model convergence.

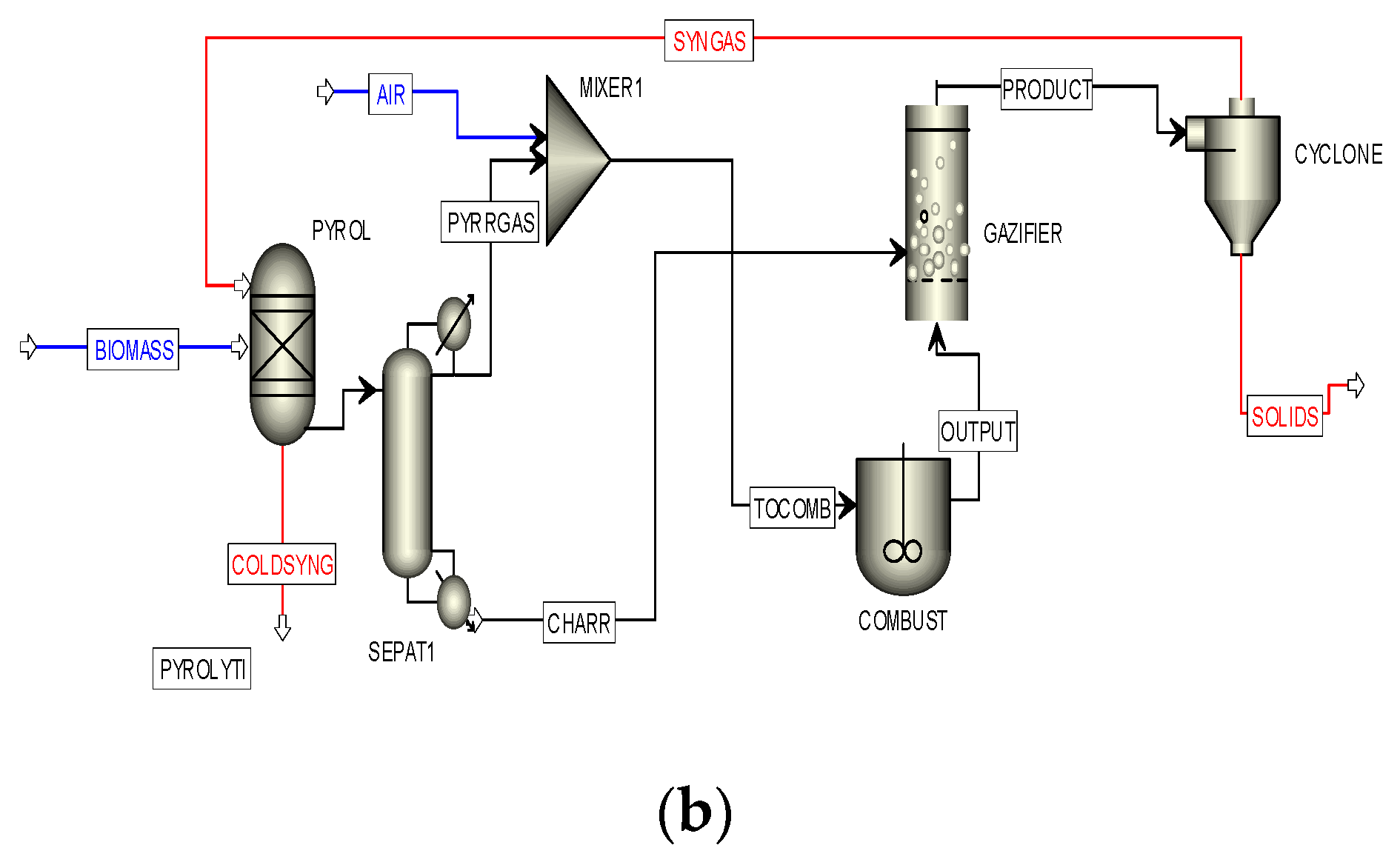

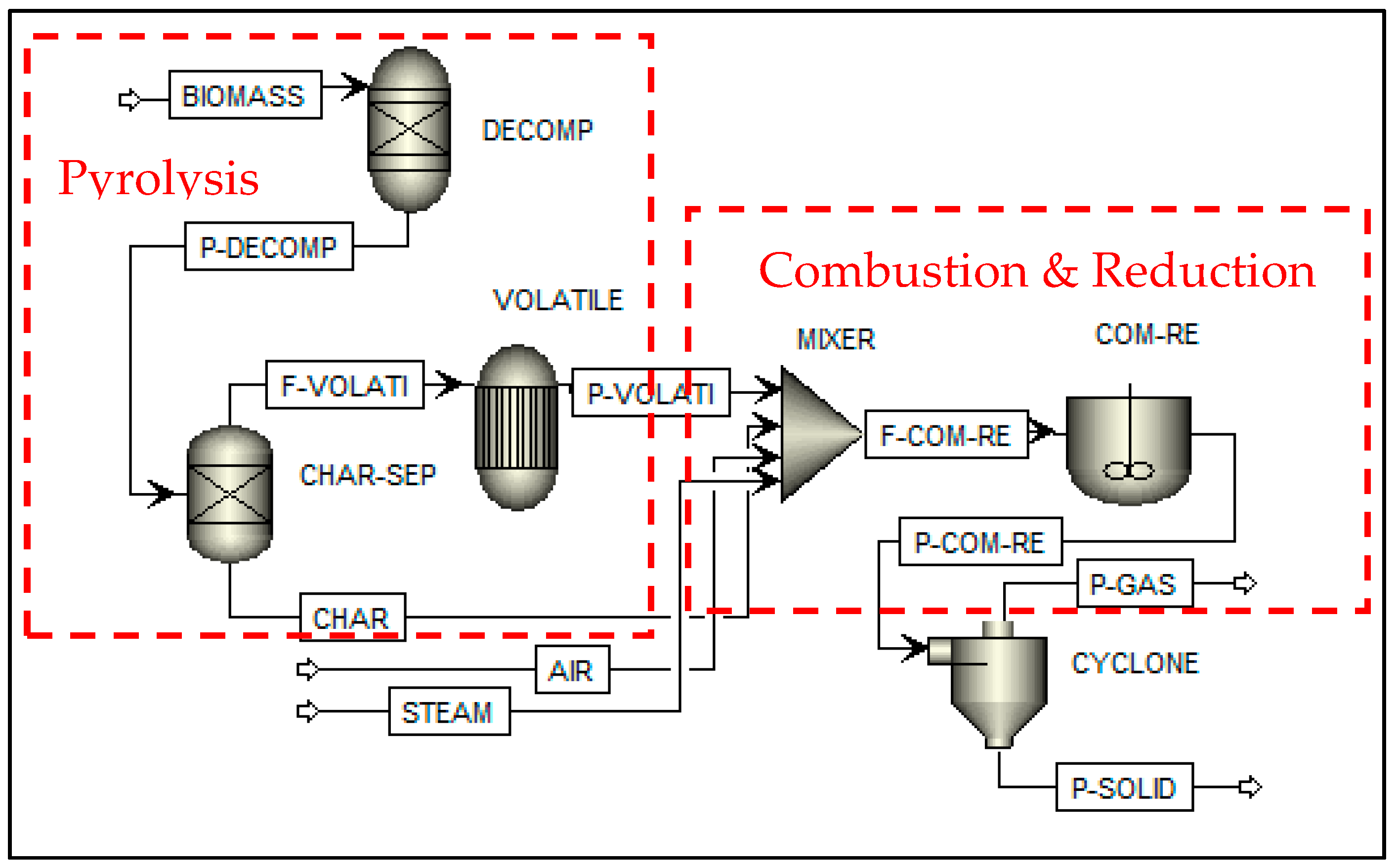

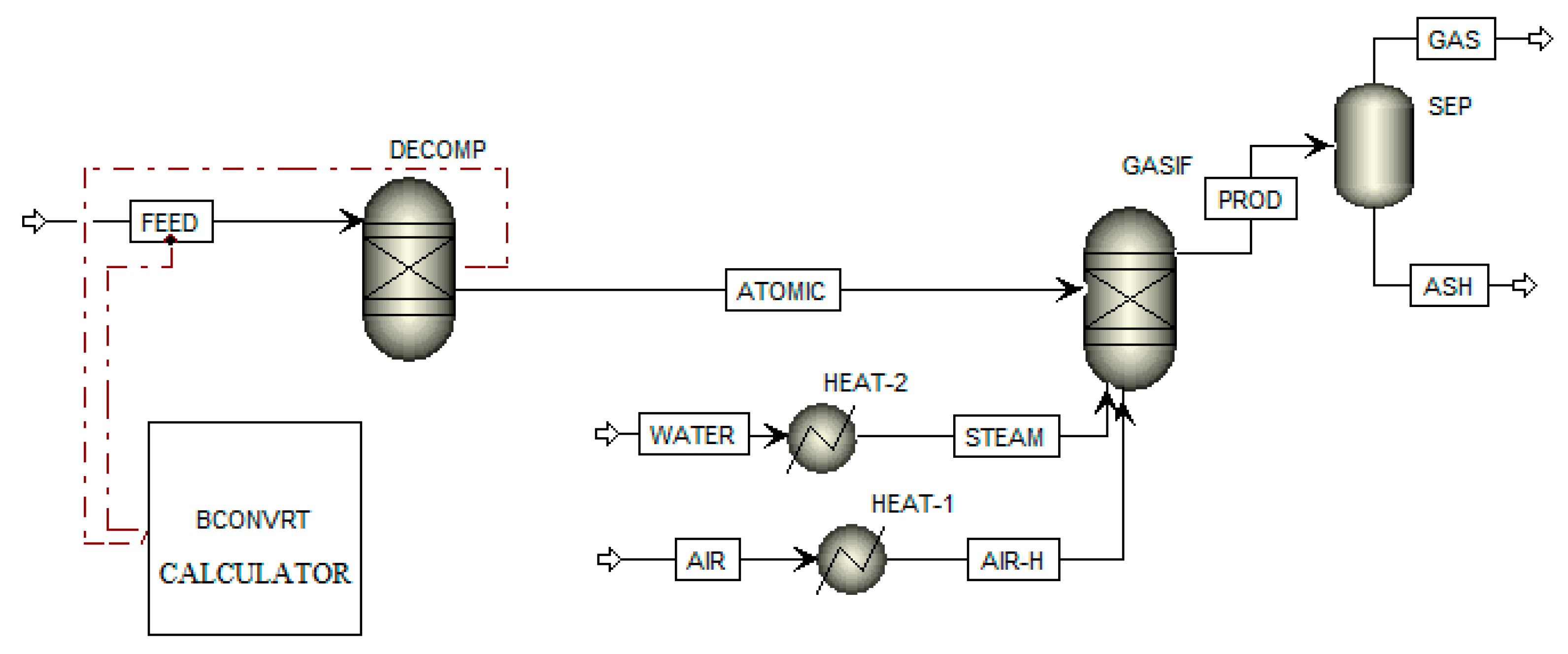

A detailed model of the gasification reactor is one of the key points to achieve an accurate process description. O Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierbkp o Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierpdf o USRKINf o USRPRESf o. This was done by splitting the gasification process into five different sub processes starting with pyrolysis or decomposition of the feed volatile and non-volatile component separation volatile reactions char gasification and finally solid gas separation.

Methane formation reaction MF C 2 H 2 CH 4. Nonconventional compenent is solids that are not pure Chemical Species. Yes there is a tutorial as part of the help topics as far as I remember.

Developed a Gibbs free energy minimisation model for steam gasification of biomass to derive the optimum process condition for gasification. The primary goal of the study is to break down municipal solid waste MSW into multiple gaseous species including synthetic gases hydrocarbons and tar compounds in the pyrolysis stage through the theoretical yield. An original equilibrium gasification model using ASPEN PLUS was first built and validate based on existing data of a downdraft gasifier DDG.

Simulating solvent-based carbon dioxide capture in modern commercial software packages can be very challenging. Boudouard reaction BD C CO 2 2 CO. Mass fraction from birch wood used in Aspen plus simulation Gas Mixed substream mass-frac CISolid substream mass-frac CH4 00969 0 CO 05307 0 CO2 01365 0 H2 00125 0 C 0 1 H2O 01509 0.

Oxygen-steam gasification of karanja press seed cake. Drying at 100-200 C pyrolysis at 200-500 C gasification and combustion. Aspen Plus Simulation of a Coal Gasification Process Geometric Analysis.

Up to my knowledge it is the most comprehensive pyrolysis model. Fixed bed experiments ASPEN Plus process model development and benchmarking with saw dust rice husk and sunflower husk By Kotaiah Naik Download pdf. A biomass gasification process in ASPEN Plus.

A model for biomass gasification in dual fluidized bed DFB reactors by coupling. This paper presents a novel ASPEN Plus equilibrium model for MSW pyrolysis and plasma gasification associated with experimental validation. A biomass gasification process is presented.

Tar was not considered in the model and char conversion was taken as 100. The simulation results obtained using ASPEN Plus for coal gasification process was explained based on the following simplified gasification reactions. Aspen Plus Getting Started Building and Running a Process Model Tutorials covering basic use of Aspen Plus.

The gasification temperature is 750 C. These steps are frequently. However the major steps of working with Aspen are similar to what is depicted below.

Process simulation and sensitivity analysis of indirect coal gasification using aspen plus model By Fahim Uddin and Syed Ali Ammar Taqvi Coal gasification by indirect heating in a single moving. The gasification process may be split into steps. Getting Started with Aspen Plus or Aspen Properties.

Δ H r -75 kJ kmol. When we choose NC properties and select HCOALGEN for enthalpy and DCOALIGT for density then system asks for the proximate ultimate and sulfate analysis.

Processes Free Full Text Simulation Of Prosopis Juliflora Air Gasification In Multistage Fluidized Process Html

Biomass Gasification Model In Aspen From 12 Download Scientific Diagram

Energies Free Full Text Simulation Of Steam Gasification In A Fluidized Bed Reactor With Energy Self Sufficient Condition Html

Pdf Simulation Of Sugarcane Bagasse Gasification Using Aspen Plus Semantic Scholar

Energies Free Full Text Thermodynamic Analysis Of Biomass Gasification Using Aspen Plus Comparison Of Stoichiometric And Non Stoichiometric Models

Pdf Aspen Plus Simulation Of Biomass Gasification With Known Reaction Kinetic Semantic Scholar

Aspen Plus Simulation Of Co Pyrolysis And Gasification Of Plastic And Biomass To Syngas Part 2 Youtube

Pdf Aspen Plus Simulation Of Biomass Gasification With Known Reaction Kinetic Semantic Scholar

0 comments

Post a Comment